ラバースプリング

- 性能・特長

- 仕様・規格

- 主な用途

-

優れた防振性能

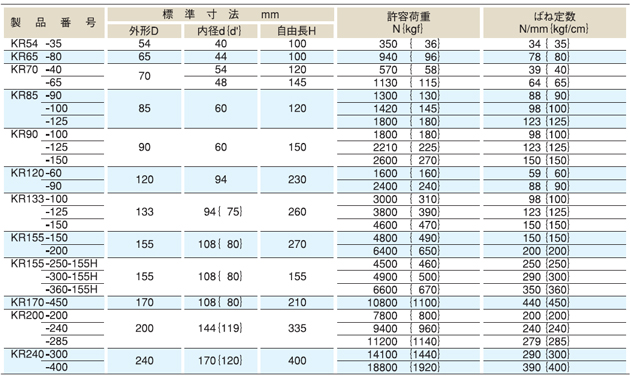

ゴムとコイルばねを組合わせた円筒形の複合ばねの構造により柔らかいばねが得られ、たわみが大きく

取れます。大きい耐荷重性

金属ばねと特殊合成ゴムの複合ばねのため、座屈することなしに高荷重の負荷性能が得られます。

減衰効果が大きい

高損失係数を持つ特殊合成ゴムの使用により、共振振幅の低減効果に優れます。

防音緩衝効果に優れる

金属ばね単体で使用する場合に見られるサージング現象がなく騒音の発生がありません。また、特殊構造から衝撃吸収性能にも優れます。

耐久性、耐薬品性に優れている

高度の形状設計技術および配合技術によって完成されたものであるため、使用中の機械的劣化および

酸素・オゾン・薬品等での化学的劣化にも極めて優れています。取付けが容易

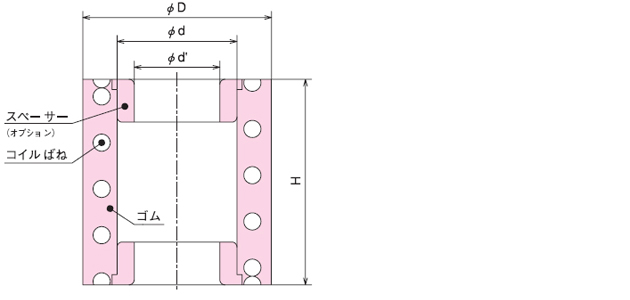

ラバースプリング内径面にガイドピンを置き、機械を載せることで取付けができます。もし内径が大きすぎる場合にはスペーサーを使用してください。別途で承ります。

関連リンク