材料開発技術

材料開発における理念

- ・倉敷化工の材料開発は高分子材料の配合・加工・評価技術を創出し、深化させています。 この技術を高度に連携させることで、様々な要求特性を実現し、付加価値の創造に貢献します。

- ・倉敷化工の材料開発は高分子材料の配合・加工・評価技術を創出し、深化させています。 このことは付加価値の高い製品の提案に貢献し、様々な要求特性を実現します。

- ・倉敷化工の材料開発は高分子材料の配合・加工・評価技術を創出し、深化させています。 このことは付加価値の高い製品の提案に貢献し、お客様に感動していただける商品・サービスの提供につながります。

保有技術

ゴム材料の配合・加工・評価を重要な技術と位置づけています。

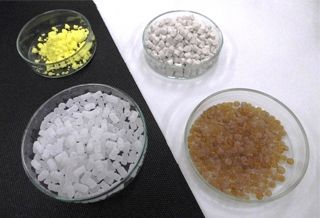

ゴム弾性体は天然ゴムなどのポリマーと様々な配合剤を混練した生ゴムを任意の温度と時間で化学反応させ製造します。

その化学反応は加硫と呼ばれ、塑性変形する生ゴムから弾性体へと変化させます。

配合技術

様々な配合剤を駆使して、自動車用防振ゴム、ホースで要求される防振性、耐熱性、耐久性などの性能を高い次元で実現するゴム材料を提供します。

また、自動車用ゴム材料で培った配合技術を一般産業機器向けに応用し、様々な防振デバイスを提案します。

加工技術

ゴム材料の混練技術、加硫成形技術、金属などとの複合製品の場合は接着技術が重要な加工技術に挙げられます。

混練技術はゴム材料の均質化を実現し、耐久性や機械的強さに寄与します。

加硫成形技術は複雑な形状の実現、加硫反応の高速化による生産性の向上に貢献します。

接着技術は異種材料である金属とゴムの複合を実現し、複合体の強度は接着試験において界面での剥離ではなく母材破壊を原則としています。

評価技術

材料の物理特性評価技術、耐環境性評価技術、素材の定性、定量を行う分析技術があります。

材料加工性、加硫反応性、機械的特性などの品質性能評価や熱、オゾン、接触する化学物質、繰り返し歪などの要因による複雑なゴム劣化メカニズムの解明に応用されます。