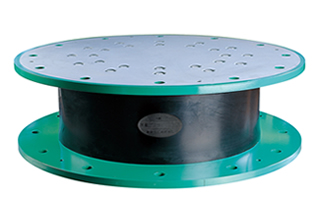

天然ゴム系積層ゴムアイソレータ

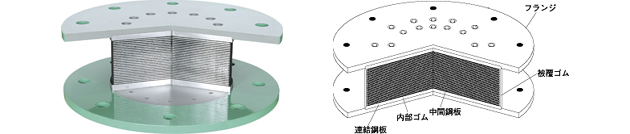

積層ゴムの構造

積層ゴムアイソレータは建物荷重を支持し、地震時には水平方向に柔らかく変形することで、地震力の建物への伝達を軽減する役割を担う重要な製品です。

ゴムと鋼板を交互に積層し、金型にセットして成形します。製造工程の重要ポイントでは

さまざまな検査を行い、製品の品質を保証しています。

製品性能

中間鋼板露出型の優位性

クラシキ積層ゴムアイソレータは中間鋼板が側面に露出した中間鋼板露出型です。

さらに、中心孔が無く、高面圧でも安定した性能を発揮します。

中心孔無しの強い構造

クラシキ積層ゴムアイソレータの構造は、中心孔無しの増強構造。

当社独自の開発技術で中心孔を必要としない積層ゴムアイソレータの生産を実現しました。

中心孔が無い積層ゴムアイソレータは、軸が強く、高面圧でも優れた性能を発揮します。そのため、安定した復元力を維持することが可能であり、積層ゴムが大変形した場合も、座屈しにくい構造となっています。

高純度天然ゴムによる信頼性

クラシキ積層ゴムに使用されている天然ゴムは、品質の安定した原料のみを厳しい検査体制のもとに輸入して使用しています。