CAE技術

概要

CAEとは、コンピュータ技術を用いて技術判断を行なうこと(Computer Aided Engineering)を指します。

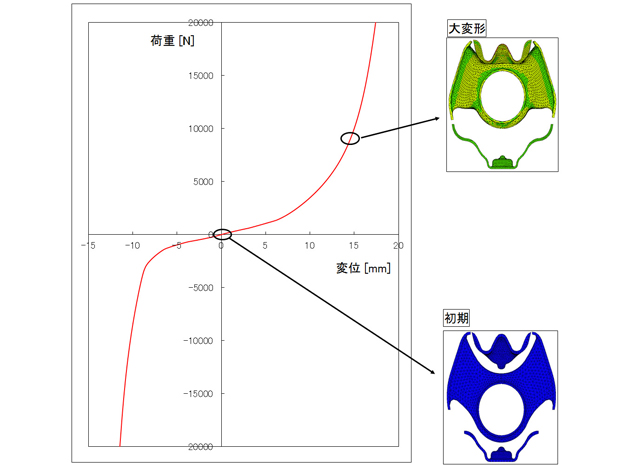

ゴム部品の特性・耐久性解析

弊社所有の均等二軸伸張試験機によりゴムの多様な材料特性を採取し、精度の高い弊社独自の解析材料モデルを作成します。

ラバー部の大変形領域までの荷重-たわみ特性解析および強度解析を行います。

これにより、耐久性や三軸ばね特性などの要求性能に対して最適なラバー形状設計を行う事ができます。

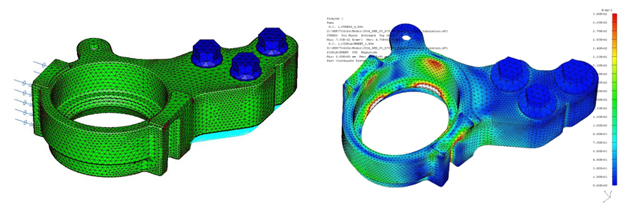

金具部品の強度解析

金具の大荷重強度および耐久性を確保するために、様々な入力に対する金具の応力解析を行います。

また、高周波領域での優れた防振性能を実現するために、金具の固有振動解析も行います。

最適形状の提供

数値最適

解析フローを自動化する事で工数を極限にまで抑えつつ、人の手では探し切れないほどの莫大な寸法(パラメータ)の組合せの中から効率良く最適形状を探索します。

強度条件・性能要件を満足させつつ、軽量で安価な製品をご提供いたします。

位相最適

提示された設計スペースの中から、密度法による効率的な除肉を行い軽量で最適な形状設計を行う技術です。

既存概念に捕らわれない斬新で安価な形状設計を実現します。

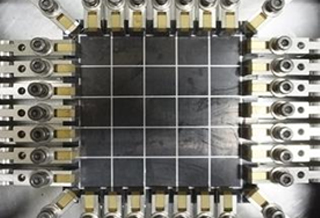

保有設備

単軸伸張試験

均等2軸伸張試験・純せん断伸張試験

体積伸張試験