CAE technology

overview

CAE refers to making technical decisions using computer technology (Computer Aided Engineering).

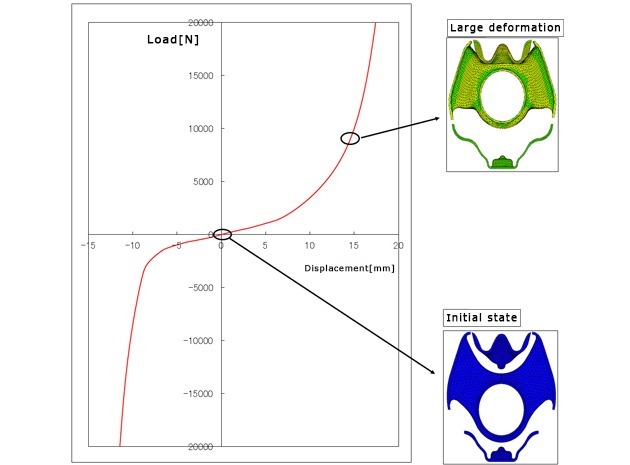

Characteristics and durability analysis of rubber parts

We collect various material properties of rubber using our own uniform biaxial elongation tester and create our own highly accurate analysis material model.

Perform load-deflection characteristic analysis and strength analysis up to the large deformation area of the rubber part.

This makes it possible to design the optimum rubber shape for required performance such as durability and triaxial spring characteristics.

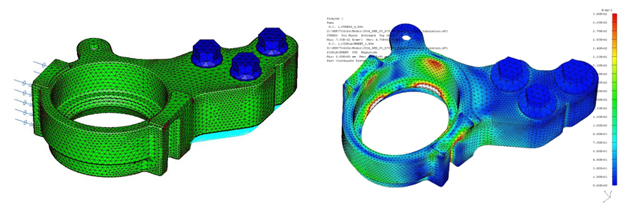

Strength analysis of metal parts

In order to ensure the large load strength and durability of metal fittings, stress analysis of metal fittings is performed for various inputs.

In addition, in order to achieve excellent anti-vibration performance in the high frequency range, we also perform natural vibration analysis of metal fittings.

Providing optimal shape

Numerical optimization

By automating the analysis flow, the number of man-hours is minimized, and the optimal shape is efficiently searched for from a huge number of combinations of dimensions (parameters) that cannot be searched by hand.

We provide lightweight and inexpensive products while satisfying strength and performance requirements.

phase optimum

It is a technology that efficiently removes meat from the presented design space by the density method and designs a lightweight and optimal shape.

We realize innovative and inexpensive shape design that is not bound by existing concepts.

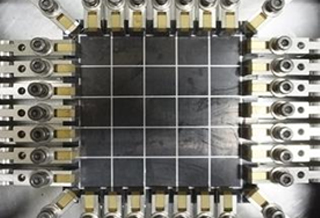

Owned equipment

Uniaxial extension test

Equal biaxial elongation test/pure shear elongation test

Volume extension test